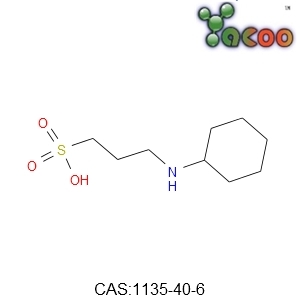

N-Cyclohexyl-3-aminopropanesulfonic acid (caps), is

a biological buffer, mainly used in biochemical diagnostic kits, DNA /

RNA extraction kits and PCR diagnostic kits. The preparation process of caps has been receiving attention. This article will introduce three production methods of caps.

The first method:Dissolve

cyclohexylamine in ethanol, then slowly add propionolactone, control

the reaction temperature at about 50 ℃ through the feeding speed; after

adding, continue the heat preservation reaction for 4 hours, filter and

dry the caps crude. Then dissolve the crude 3- (cyclohexylamine) propanesulfonic acid (caps)

in 100g of hot water and add ethanol, cool and crystallize, filter and

dry to obtain the finished product of 3- (cyclohexylamine)

propanesulfonic acid (caps).

This method has a simple process but the product solution of the produced caps has poor absorbance and has a problem of suspended matter, which results in low yield and poor quality during production.

The second method:Dissolve

propionolactone in N, N-dimethylformamide according to the weight

ratio; add cyclohexylamine according to the preset speed, and control

the reaction temperature at 30 ℃ through the preset speed of feeding;

continue the heat preservation reaction for n hours after feeding, and

then filter and dry to obtain crude caps product; dissolve the caps in hot water, then add ethanol, and then cool to 0 ℃, and then dry to obtain finished product of caps.

There

are similarities in the preparation process of these two methods, the

latter is an improvement of the former, and the yield of the resulting

product is high and the quality is good.

The third method:Dissolve

1,3-propane sultone with organic solvent A to obtain organic solution

containing 1,3-propane sultone, dissolve cyclohexylamine with organic

solvent B to obtain organic solution containing cyclohexylamine; The

organic solution of propane sultone and the organic solution containing

cyclohexylamine are simultaneously pumped into the micro-channel reactor

to react to obtain the reaction liquid; then the obtained reaction

liquid is precipitated by freezing crystallization of the crude caps and then passed through nitrogen pressure filtration to obtain the finished caps product .

The

operation process of this method is simple and stable and controllable,

and the production capacity and product yield are improved.

In summary, the preparation of caps mainly

uses propane sultone and cyclohexylamine as raw materials. Through

continuous development, standards such as simple process, high yield and

good quality are the pursuit of caps production, which is conducive to high quality and high purity caps Production will help to further expand the application of caps.

没有评论:

发表评论