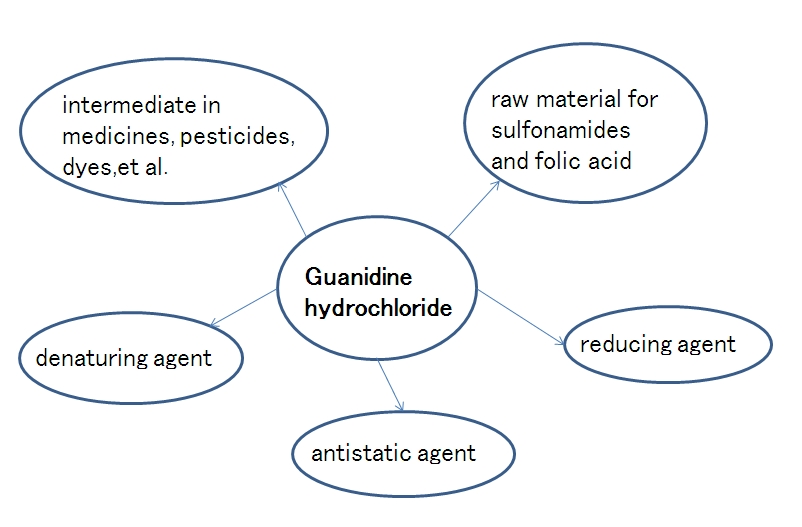

Guanidine hydrochloride is

often used as an intermediate in medicines, pesticides, dyes and other

organic compounds, it is also an important raw material for sulfonamides

and folic acid; it can be used as a strong denaturants in the

extraction of total RNA from cells. The proportion of traditional

refined guanidine hydrochloride synthetic preparation process is simple,

and the operation in each process is not strict: such as mixing

impurities during stirring, temperature is difficult to observe, and

weighing is inaccurate. Both of them lead to the problem that the low

purity of the Guanidine HCL and the incomplete reaction. Then how to solve these problems?

Researchers

have developed a new guanidine hydrochloride synthetic preparation

process, which solves the shortcomings of the prior part. As a

preference, the following steps are included:

1.

Ratio: (1) dicyandiamide 350g, ammonium chloride 450g, ammonium

carbonate 50g, (2) dicyandiamide 168g: ammonium chloride 203g: ammonium

carbonate 19g; weighting by electronic precision balance, one

prefabricated, another reserved.

2.

Preparation, adding the pre-formed raw materials to the reaction kettle

with electric heating function, adding the spare raw materials to the

porcelain quality cup (high-temperature disinfection after washing and

drying before operation), and uniformly stirring the raw materials in

reaction kettle through the non-front glass rod. The raw materials in

the porcelain cup are are added to the reaction kettle after the raw

materials in that are uniformly stirred;

3, heating, the reactor is heated to 170°C±5°C, and monitored by a temperature sensor;

4. The synthesis reaction is carried out in a reactor environment of 170°C±5°C for three hours;

5. Preparation was completed, and the reaction vessel was opened to obtain 385 g of hydrazine hydrochloride.

The

preparation process not only has a precise ratio, the reaction

temperature is convenient for observation and control, no impurity is

mixed during stirring, the reaction is complete, and the prepared

guanidine hydrochloride is also high in purity.

Edited by Suzhou Yacoo Science Co., Ltd.

2019年3月13日星期三

2018年9月7日星期五

Preparation Of Graphene Using Guanidine Hydrochloride As Reducing Agent

Guanidine hydrochloride,

which is often used as an intermediate in medicines, pesticides, dyes

and other organic compounds, is an important raw material for

sulfonamides and folic acid; it can be used as a strong denaturants in

the extraction of total RNA from cells, and used for denaturation and

complexation of proteins. It can be used as an antistatic agent for

synthetic fibers. In addition, it can also be used as a reducing agent

to prepare graphene.

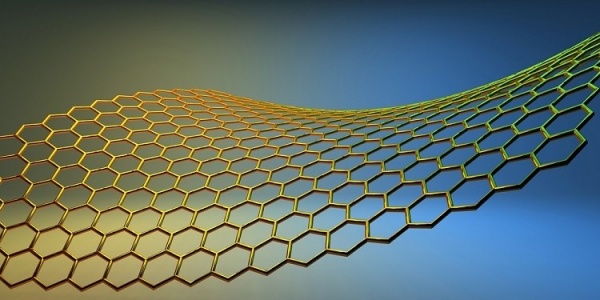

Graphene

is a two-dimensional crystal composed of carbon atoms with only one

layer of atomic thickness. It is an ultra-thin material with high

strength and toughness. It has a large breaking strength which is 200

times more than steel. It has 20% stretching range and excellent

electrical conductivity.

Due

to its unique quantum effect and excellent electrical, thermal and

mechanical properties, graphene has broad application in nanoelectronic

devices and integrated circuits, flexible electronic devices, ultra-high

sensitive sensor devices and other new electronic devices, composite

materials, solar cells, super capacitors, hydrogen storage materials,

etc.

The Existing Preparation Method

At

present, preparation methods of graphene mainly include physical

mechanical stripping method, vapor deposition method and chemical

method. Mechanical methods include micro-mechanical stripping methods,

epitaxial growth methods and heating of SiC. It is difficult to prepare

graphene with large area and uniformly thick.

Compared

with physical methods, chemical method for preparing graphene has a

high yield. It has the advantages of simple preparation method, low cost

and large-scale production, and thus becomes a common method for

preparing graphene. However, in the reduction of graphene oxide, the

selected reducing agents are mainly hydrazine hydrate and its

derivatives, NaBH4, p-phenylenediamine, sulfur compounds, etc. Most of

the reducing agents are toxic and explosive, which is not conducive to

large scale production.

Therefore, it is necessary to develop a simple, efficient, low-cost and environmentally friendly method.

The researchers developed a method for preparing graphene with guanidine hydrochloride (CAS 50-01-1) as a reducing agent [1]:

(1)

Dispersing graphene oxide in water, treating with a cell disrupter for

20~90min and then continuing ultrasonic for 10~60min to obtain a

uniformly dispersed graphene oxide with a concentration of 0.1~10mg/mL;

(2)

Adding soluble polymer (one of polyvinylpyrrolidone, polyacrylamide,

polyvinyl alcohol, polyethylene glycol, hydroxymethyl cellulose,

polyacrylic acid) to the graphene oxide dispersion, ultrasonic

dispersion 5~30min, a mixed solution of polymer and graphene oxide is

obtained, and the mass concentration of the soluble polymer in the mixed

solution is 0.01~0.1 mg/mL;

(3)

Adding guanidine hydrochloride to the above mixed solution, the mass

ratio of guanidine hydrochloride to graphene oxide is 10:1~100:1, and

adding alkaline solution (10%~28% ammonium hydroxide, 0.1~5mol/L NaOH

solution, 0.1~5mol/L KOH solution) to adjust the pH to 8~12, stir in the

oil bath (60~100°C), the reaction time is 1~5h. The water-soluble

graphene is obtained by centrifuging and washing.

The

preparation method has the advantages of simple preparation process,

low equipment requirement, and easy preparation of graphene in large

quantities; the presence of the soluble high molecular polymer greatly

improves the water solubility of the graphene, and is also beneficial to

the further preparation of the graphene film. Guanidine hydrochloride (Guanidinium chloride)

can be used as a reducing agent to prepare graphene which can be stably

dispersed in an aqueous solution, and the prepared graphene can be used

for constructing sensor and electrical device.

Reference

[1]

Ma Qi, Song Jinping, Guo Yong, et al. A method for preparing graphene

with guanidine hydrochloride as a reducing agent. CN104261393B, 29 June

2016.

Edited by Suzhou Yacoo Science Co., Ltd.

订阅:

博文 (Atom)